Services

We accompany you through the entire life cycle of your transformation project. Our aim is to set new standards in the metal industry together with you.

Designs for the Metals Industry – Concepts for the Future!

Digital Transformation

The need for digital transformation in the metal industry has significantly increased in recent years. Several reasons contribute to this:

- Strategic realignment of the company

- Outdated, unsupportable systems

- Obsolete organizational structures and demographic changes

- Need for standardization and harmonization

- Introduction of new technologies and artificial intelligence as a basis for further innovations

These factors are crucial for the strategic alignment and design of your company's digital transformation. With our many years of experience and expertise, we support you in this phase with recommendations on benchmark processes in the industry, current development trends, and scenarios for system integration.

Once the strategy has been defined and the commitment of top management has been obtained, we will work with you to develop a detailed implementation plan - the roadmap, also known as the "program". Given the historically grown, heterogeneous system landscape in the metal industry and the associated complexity, it can make sense to divide the roadmap into sequential phases that build systematically on one another. Each phase can be viewed as an independent project that is part of this overall program. The finalized roadmap serves as a solid basis for budgeting and strategic planning of the entire program and the associated projects. It is advisable to carry out regular reviews in order to adapt the plan to the situation. These iterations make it possible to make optimizations and continuously refine the strategy based on experience gained and feedback from stakeholders.

An exemplary IT roadmap that includes multiple phases as well as the key functionalities and system Go-Lives

Program and project management

Every program brings different requirements for execution. For example, agile project management methods are particularly suitable for very complex, development-intensive projects with clearly defined goals. Programs that initially involve capturing requirements for solutions, organization, and processes require well-planned phases to be implemented effectively. This is where we bring in our expertise by precisely defining the scope, organizational procedures, automation, and methodologies. During the program setup, we establish the project environment, documentation guidelines, and project methodology.

We believe that a successful project can only be achieved through the harmonious interplay of all relevant factors, which include:

- Realistic goal setting

- Solid project organization that can develop dynamically

- A thorough understanding of processes

- Clear responsibilities, and

- Strong problem-solving skills.

All these aspects must be continuously aligned with the project goals through effective project management. An integrative, continuous project controlling and monitoring of project progress using predefined MS4Process dashboards are essential.

Integration management

Integration management in IT and process transformation projects is crucial to ensure effective linkage and coordination of system components, processes, and other project aspects, thus contributing to the achievement of project and overarching business goals. Mert & Strätling Process Management considers integration management as a central staff function in projects or programs, bringing together the following key areas:

Solution design

Our solution design is process-oriented. When developing software solutions, we focus on business processes and we consistently model the technical aspects of the respective domain in a domain-driven design. This approach aims to close the gap between the technical requirements and the technical implementation by focusing on a deep understanding of the business processes and the specific requirements of the domain.

A process-oriented solution design is based on a detailed analysis of the business processes with the aim of optimally supporting them and increasing their efficiency. It is characterized by flexibility for adaptation to the business environment and precisely models workflows, decision points and interactions between system components and user roles, even in the To-Be process.

Specifying the solution design in a domain-driven manner means that the focus is on the domain and its expertise. By applying Domain-Driven Design (DDD) principles, a close link between the software architecture and the business goals is achieved.

Another important aspect of domain-driven and process-oriented solution design is the involvement of stakeholders and subject matter experts in a continuous improvement process. This makes it possible to establish feedback loops and ensure that the solution developed reflects real requirements and offers real added value for the company. Agile development practices support this approach by enabling iterative development cycles and flexible adaptation to changing requirements.

Process management

Structured requirements analysis

An effective requirements analysis is often more challenging than is generally assumed. Not every requirement that can be formulated turns out to be actually relevant upon closer inspection.

Our goal is to give your organization a solid understanding of what constitutes real requirements and how to formulate them in a meaningful way. In addition, careful evaluation of requirements is crucial. What is considered extremely important within one department may become less important in the context of the entire project. That's why it's essential to involve everyone who contributes to the project's goals from the start.

A thorough understanding of the current processes and their documentation is essential for the success of the requirements analysis. This analysis serves as a bridge from the current to the desired state of processes and organizational structures.

We offer support with standardized and proven methods to guide you in the precise formulation and evaluation of your requirements.

Process modelling and process design

The two founders of Mert & Strätling Process Management GmbH began their careers at IDS Prof. Scheer and were very fortunate to work in an area that recognized process orientation and industry focus as very important. We are firmly convinced that IT projects with process transformation and organization can only be successful together.

Talking about processes forces those involved to think outside the box, beyond the department and their own workplace. A suitable method and sufficient structure are then needed to develop a common process language that becomes an asset of an organization.

And that's exactly where we come in: we model the essential, critical processes, both the actual and the target processes, right from the requirements phase. The goal is to create a coordinated process map for the organization and derive the future solution from it.

Process development and improvement

In many projects, the point of process development is often neglected and only many years later does one realize that the path of continuous improvement has long since been abandoned. At this point, the organization is faced with another "big bang". For business processes to function effectively within an organization, it is essential that these processes are not only implemented, but also lived and continuously adapted to new requirements.

We not only offer advice and support in this critical area, but also focus on enabling you to drive process modeling forward independently. The real added value for your organization comes from the initiative and commitment of your team. By integrating specific examples and case studies into our advice, we illustrate how effective process development increases efficiency.

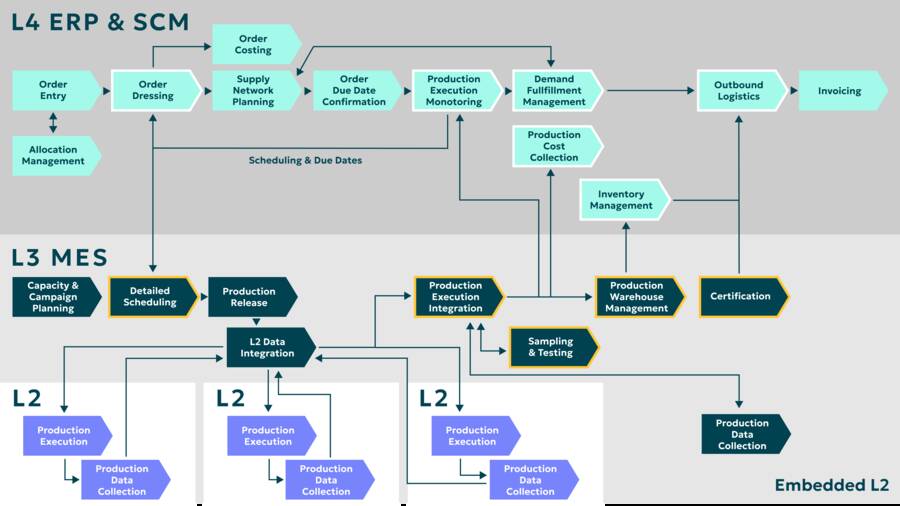

An exemplary E2E process: Integrated Order-to-Cash process

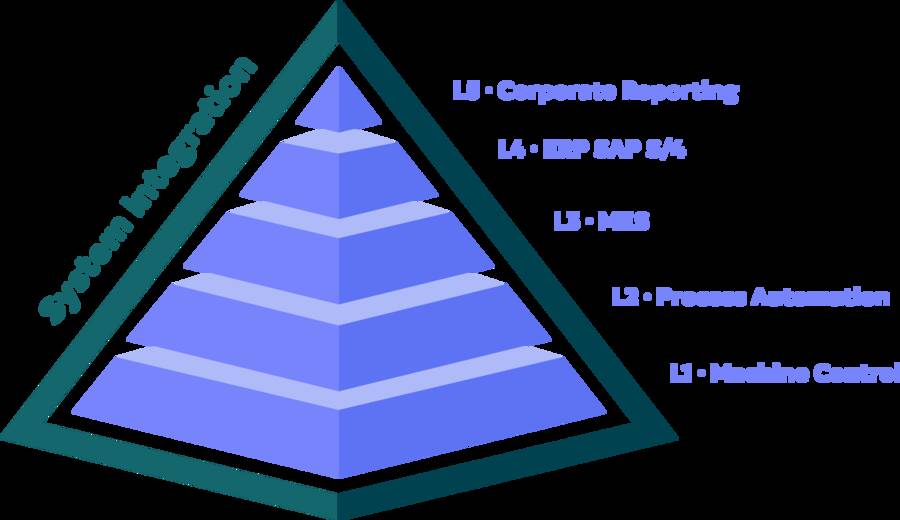

System integration

In the area of system integration, we use our extensive expertise from numerous projects. It is common project practice to integrate a wide variety of systems within a heterogeneous network. In transformation projects, ensuring stable system integration across all go-live phases is of crucial importance. In addition, it is essential to enable concepts such as parallel operation for comparison purposes when dealing with complex challenges.

The use of a uniform middleware has proven to be effective, as has the use of a powerful interface framework on platforms such as SAP S/4 for the exchange of incoming and outgoing messages. Standardized error tracking and correction is of great importance here. Monitoring the processing sequence and parameterizing parallel processing are particularly important when operating under high load. The definition of mechanisms for failure scenarios of individual systems is equally critical.

We attach great importance to avoiding the implementation of business logic within the interfaces beyond the mapping. Decisions regarding the creation of production orders or the posting of goods movements with specific movement types should be made within the business object, because the distribution of business logic across different locations is one of the biggest obstacles in complex transformation projects and can significantly increase the effort in the medium to long term.

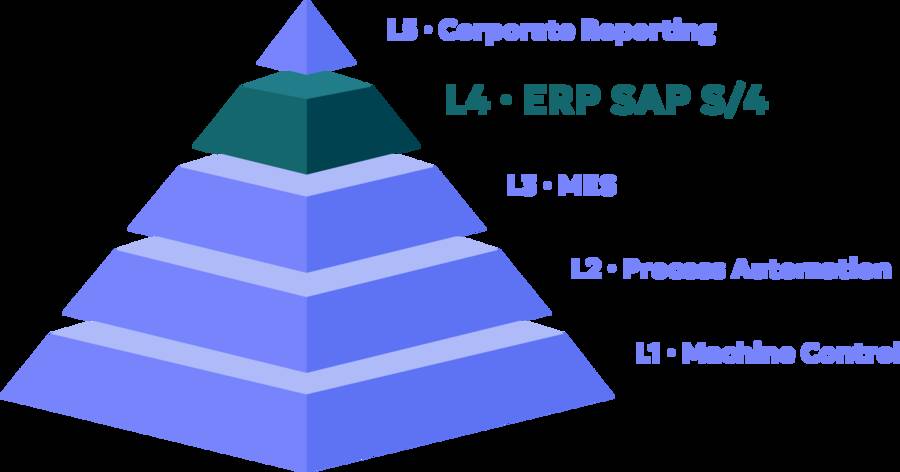

SAP S/4 implementation

Level 4 — Our expertise includes the integration of various SAP solution components. We possess deep knowledge and practical experience in core modules such as Production (PP), Sales and Distribution (SD), Variant Configuration (VC), Materials Management (MM), and Controlling (CO). Additionally, we have extensive know-how in the System Integration module Application Interface Framework (AIF). We also offer specialized knowledge in planning components such as Embedded PP/DS, which expand our solution competence. Another focus is on integrating order dressing solutions into the SAP standard, which is particularly significant for the metal industry with its need for efficient specification management. In this area, we successfully implement the leading solution QPPD from Secat and ensure smooth integration into existing system landscapes.

Furthermore, we have developed numerous customized consulting solutions for industry-specific challenges. Examples include Coil-Trim (Mixed Linear Programming), a scheduling cockpit that integrates production planning and the transportation chain, or requirement specifications with QPPD with full integration into the SAP standard. Our extensive experience enables us to effectively incorporate these and similar solutions into your implementation projects, bridging gaps to the SAP standard where pure standard solutions become inefficient.

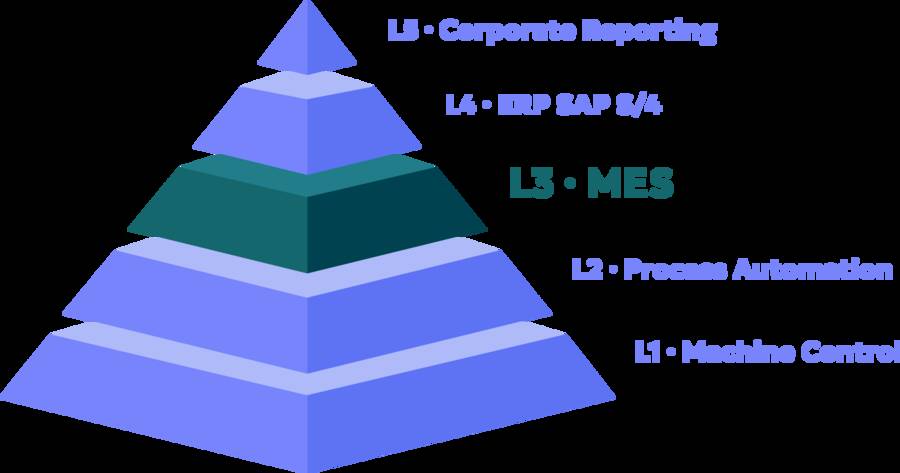

MES design & implementation

Our expertise extends to the custom design and implementation of client-specific MES systems as well as the enhancement of standard MES systems. Seamless integration of MES systems into the overarching ERP management system (Level 4) and integration to process automation (Level 2) are also among our core competencies. Our offerings particularly focus on developing highly automated processes and applications for the production environment, including quality management, also known as Non-Conformity. We start with a detailed analysis of processes and their specific requirements to derive criteria for the relevant business objects such as orders, melts, batches, etc. The scope of the processes is determined by the transformation strategy and existing facilities. Typically, processes are oriented to the phases:

- Liquid phase

- Hot phase

- Cold phase

- Finishing

Once these phases are analyzed and the requirements are gathered, we proceed to create an ERM (Entity-Relationship Model). We specify and model the relevant objects and seamlessly integrate them into the corresponding processes while also considering the necessary methods.

Creating and, if needed, implementing cockpit designs such as order information systems, planning boards, batch tracking, and system integration monitors round out our MES system service portfolio.

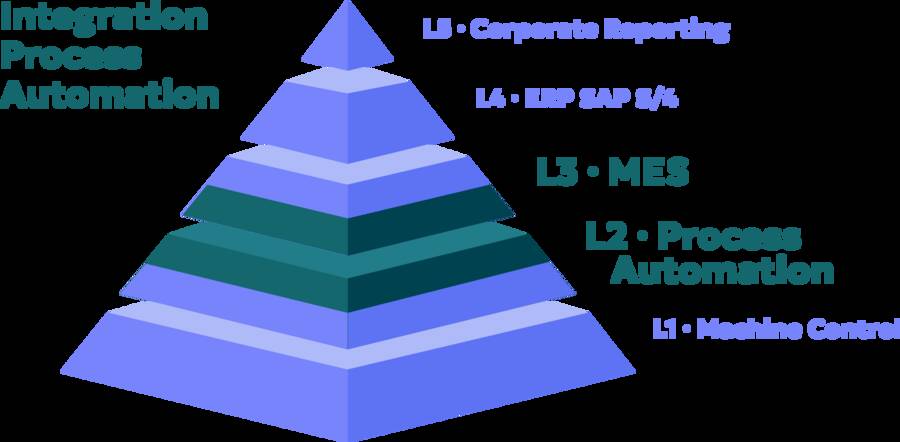

Integration Process Automation

Integrating process automation (Level 2 Systems) and ensuring the timely provision of relevant data and the correct processing of data sent from the various level 2 systems is also part of our portfolio. Our concepts focus on highly automated processes and routines with real-time interfaces. We support you in designing standardized communication processes and data transfer between facilities and the MES system.